N.B. In 2019, it having become clear that there would never be any further interest in the Track Recording Trolley in a complete working form, the mechanism was permanently disabled and the NEPTUNE computer system removed.

The trolley will remain at Christow in the foreseeable future for use as a shunter.

This section will continue to be published as a record in case it has some historical value.

By taking various measurements, the Matisa Track Recording Trolley was designed to record the condition of track and to detect faults for the information and guidance of engineers in charge of maintenance and relaying.

The Matisa trolley was the first on British Railways to give a quantitative analysis of track, in that it recorded the condition more or less as it was, rather than the effect that it had on a moving train. Previously, recording devices were used on board trains and these gave a qualitative analysis which varied according to speed and the way that the particular vehicle behaved. Because the trolley was used at low speed, it mostly eliminated this inconsistency.

The Matisa trolley was the first on British Railways to give a quantitative analysis of track, in that it recorded the condition more or less as it was, rather than the effect that it had on a moving train. Previously, recording devices were used on board trains and these gave a qualitative analysis which varied according to speed and the way that the particular vehicle behaved. Because the trolley was used at low speed, it mostly eliminated this inconsistency.

The trolley weighs 10 tons and is propelled by a Leyland 370 diesel engine driving through a hydrostatic gearbox. It records at up to 15 m.p.h. on plain line and 5 m.p.h. over points and crossings. After the bogies have been picked up and the rigging stowed—an operation that takes but a little time—the trolley can run light at up to 40 m.p.h. Movements of the various probes and sensors are transmitted to ball-point recording pens which inscribe a roll of paper driven across a table by gears from the road wheels.

Twist is the most important of the track features and is sometimes recorded on its own. This can be done at the trolley’s top speed because the linkage between the axles is permanently engaged. Twist conditions are the most difficult for railway vehicles to ride. Especially with wagons having short, rigid wheelbases, serious twist faults could lead in the worst case to unloading of a wheel and possibly the flange climbing the rail.

Like in the old days, when the “whitewash van” left its mark on the track in the vicinity of faults which had induced lateral or vertical jolts, this trolley has two paint nozzles triggered automatically by degrees of twist: red for faults requiring immediate attention and yellow for those which should be rectified at the earliest opportunity.

Like in the old days, when the “whitewash van” left its mark on the track in the vicinity of faults which had induced lateral or vertical jolts, this trolley has two paint nozzles triggered automatically by degrees of twist: red for faults requiring immediate attention and yellow for those which should be rectified at the earliest opportunity.

Trolleys once operated over all the passenger-carrying routes of B.R. and over selected freight-only lines at intervals of between three months and a year.

Scrutinizing the traces produced by the trolley required considerable time by skilled staff and so an on-board computer system was later installed. It was called Neptune, and this explains the devices emblazoned on the doors and at each end of the vehicle. The name was somewhat contrived from North Eastern Electronic Peak Tracing Unit and Numerical Evaluator. Neptune converted the mechanical recordings into numerical data which could be output at intervals or fed as punched tape into a base computer. Programmes of work for gangs and machines could then be obtained, not only for prompt implementation, but for say a year later based on the rate of deterioration of track established by successive Neptune runs.

British Railways bought a total of 13 trolleys from Matisa of Switzerland between 1957 and 1967. In 1979, they were largely superseded by the High Speed Track Recording Coach, which operates at up to 125 m.p.h. in train formation. The fleet of trolleys was reduced to five and all but one were withdrawn in 1987 when the Class 150 Track Recording Unit entered service.

British Railways bought a total of 13 trolleys from Matisa of Switzerland between 1957 and 1967. In 1979, they were largely superseded by the High Speed Track Recording Coach, which operates at up to 125 m.p.h. in train formation. The fleet of trolleys was reduced to five and all but one were withdrawn in 1987 when the Class 150 Track Recording Unit entered service.

Since then, new service train recorders, which relay data instantly, have been introduced. And there are now hand-held devices but these do not cause the track to react.

This trolley, built in 1967, was originally allocated to the Southern Region, being transferred to the Western Region in 1983. In 1987, it was put into store at Swindon and later moved to Exmouth Junction where it was planned to convert it to an inspection trolley. This plan was dropped partly because the preference was for a lighter vehicle that could easily be taken off rail. After the denationalization of B.R., it became the property of Compactors Engineering Ltd., which firm sold it to the E. & T.V.R. in 1997.

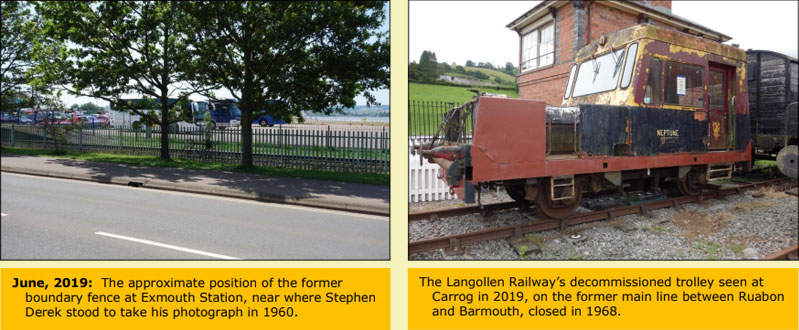

It is thought that all the rest of the trolleys have been broken up, with the exception of the one claimed by the National Railway Museum and the one sold to the Llangollen Railway.

The E. & T.V.R. trolley has had its electronics disconnected but is otherwise in full working order. It would be useful to a private railway, enabling a small gang to travel to site in comfort, taking with it a complement of tools and equipment. Track geometry faults could be found, corrected and immediately tested. The trolley could also be used as a mount for functions such as weed spraying, load gauging and flailing.

The E. & T.V.R. trolley has had its electronics disconnected but is otherwise in full working order. It would be useful to a private railway, enabling a small gang to travel to site in comfort, taking with it a complement of tools and equipment. Track geometry faults could be found, corrected and immediately tested. The trolley could also be used as a mount for functions such as weed spraying, load gauging and flailing.

Being able to make a periodic full recording run over a line and having a series of annotated traces to refer to, would surely strengthen an operator’s safety case, especially one seeking a higher speed limit.

The trolley has a straight air brake system which could be adapted to service a train pipe so that a trailer—a HYFIT for example—could be conveyed. The buffing and drawgear were originally intended for emergency use, or when conveyed at the tail of a train (not a British practice, as far as is known).

The E. & T.V.R. has no immediate need for the trolley and would be happy to come to a very reasonable arrangement with any railway for its hire. It would need overhauling and calibrating. The trolley has been examined by a Matisa engineer, who came all the way from Lausanne, and the firm advises that it could be fitted with a modern computer system for around £300,000.

To learn more and to arrange a demonstration, please contact the railway.

"Yet another illustration of science unobtrusively ensuring the comfort and safety of millions of people."

The technological advance which these trolleys made possible was recorded by British Pathé in this short film documentary made in 1959:-

The movement of trolleys was always shown on notices, along with the special conditions which took account of the trolleys' characteristics, whether recording or running "light."

When Tony Hill asked his old pals if any of them had kept such a notice, Stephen Derek, a former B.R. manager, was prompted to reply: "On reading this, I recalled an early photo I'd taken of a 'Swiss Matisa Track Recording Machine' leaving Exmouth, for Exeter, on Sunday 8th May, 1960, a few months following my transfer to the Trains Office at Exeter Central."

The photograph is reproduced here with Stephen's kind permission.

If Stephen were to take up that same position today, he would be standing in the middle of Marine Way, part of the road expansion works that necessitated the virtual destruction of the station. But, in 1960, looking at the Southern's grand rail gateway to Exmouth of 1924, few could have guessed what the future held.

The trolley is leaving Platform One in full recording mode, with probably an Exmouth Junction Driver acting as Pilotman standing at the door; being a steam man, he may have found the cab too confined.

The line in the foreground served Platform Two, part of which forms the pocket station in use today.

To the left were Platforms Three and Four. There was a space between the lines serving Platforms Two and Three which must have been left for an engine release road, but this was filled with beds containing flowers and shrubs. The space was wider still immediately in front of the camera to allow for the box (right of camera), with its "bridge" where the signalmen gave and received the tokens for the two single line branches.

At the end of each platform were lattice-work bracket signals which, as in the one seen, could allow a train to proceed from each platform to either the main (Exeter) or branch (Budleigh).

In the background can be seen the goods shed, while out of sight are the loco shed, platform canopies and fine frontage, and the harbour branch.